Fire safety is paramount in any setting, especially in churches and public facilities. Portable fire

extinguishers serve as a first line of defense against small fires. Therefore, regular inspections are critical to ensure they function properly when needed.

This guide breaks down the inspection process, highlighting the role of licensed contractors for annual certifications and the monthly checks that trained individuals can perform.

The Annual Certification by Licensed Contractors

The Necessity of Professional Inspections

All states require that portable fire extinguishers undergo an annual inspection by a licensed contractor. These professionals certify that the extinguishers are in working order and capable of performing according to their rating.

Investing in a few extra extinguishers as backups ensures that replacements are ready should one be used. In turn, this enhances your facility’s readiness for emergencies. In addition to annual inspections, extinguishers may need a five-year or hydrostatic inspection. A licensed contractor will keep you informed when additional inspections are required.

Fire safety is just the beginning. Ensure your church is ready for all emergencies—from fires to medical incidents and severe weather. The Emergency Preparedness Handbook offers step-by-step guidance for establishing safety protocols, training your team, and preparing for the unexpected. Get a free copy here.

Monthly Inspection Steps

1. Training and Documentation

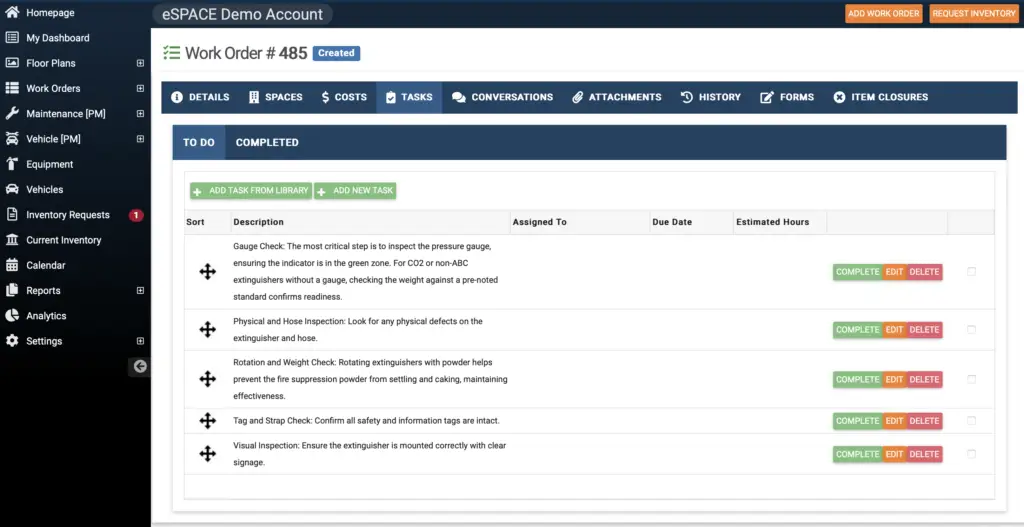

While the annual inspection requires professional certification, monthly checks can be conducted by anyone properly trained. These inspections, guided by NFPA regulations, are straightforward yet vital to ensure each extinguisher’s readiness. Incorporating these monthly inspections into your facility management software, like eSPACE, can streamline tracking and compliance.

2. Inspection Process Overview

The monthly inspection process involves several key steps to verify a fire extinguisher’s condition and readiness:

- Visual Inspection: Ensure the extinguisher is mounted correctly with clear signage.

- Tag and Strap Check: Confirm all safety and information tags are intact.

- Physical and Hose Inspection: Look for any physical defects on the extinguisher and hose.

- Gauge Check: The most critical step is to inspect the pressure gauge, ensuring the indicator is in the green zone. For CO2 or non-ABC extinguishers without a gauge, checking the weight against a pre-noted standard confirms readiness.

- Rotation and Weight Check: Rotating extinguishers with powder helps prevent the fire suppression powder from settling and caking, maintaining effectiveness.

3. Completing the Inspection

After completing the steps above, the monthly check is finalized by signing off on the tag with the date and initials. This process ensures the extinguisher’s operational readiness and serves as a record for maintenance and compliance purposes.

Leveraging eSPACE for Efficient Facility Management

Incorporating Inspections into Preventive Maintenance

eSPACE’s work order and asset management module offers an ideal platform to schedule, assign, and document these crucial safety inspections. Creating tasks for each inspection step within eSPACE ensures that everything is noticed and that a digital log is maintained for accountability and future reference.

Simplify safety inspections and facility management. See how eSPACE can help your church schedule, document, and track fire extinguisher inspections with ease. Book a free call here.

Training and Task Groups

An annual training session for staff and volunteers on proper inspection techniques can be scheduled and documented within eSPACE, ensuring that your team is knowledgeable and prepared. Task groups created for fire extinguisher inspections can be easily assigned to work orders, making the process efficient and repeatable.

The Bottom Line: Prioritizing Safety Through Regular Inspections

Fire extinguisher inspections are critical to facility safety and compliance. By adhering to a regular inspection schedule and leveraging management tools like eSPACE, churches can ensure they are prepared for emergencies and compliant with safety regulations. Investing time in training and routine inspections underscores a commitment to the safety and well-being of all who enter your facility.